离岸价格

Get Latest Price( Negotiable )

|1 Set Minimum Order

国:

China

モデル番号:

-

离岸价格:

( Negotiable ) Get Latest Price

ロケーション:

China

最低注文量の価格:

-

最低注文量:

1 Set

パッケージの詳細:

Standard pacakges

納期:

15 days

供給能力:

100 Set per Month

支払いタイプ:

T/T, L/C, Western Union

China

連絡先担当者 Camille

Zhengzhou, Henan

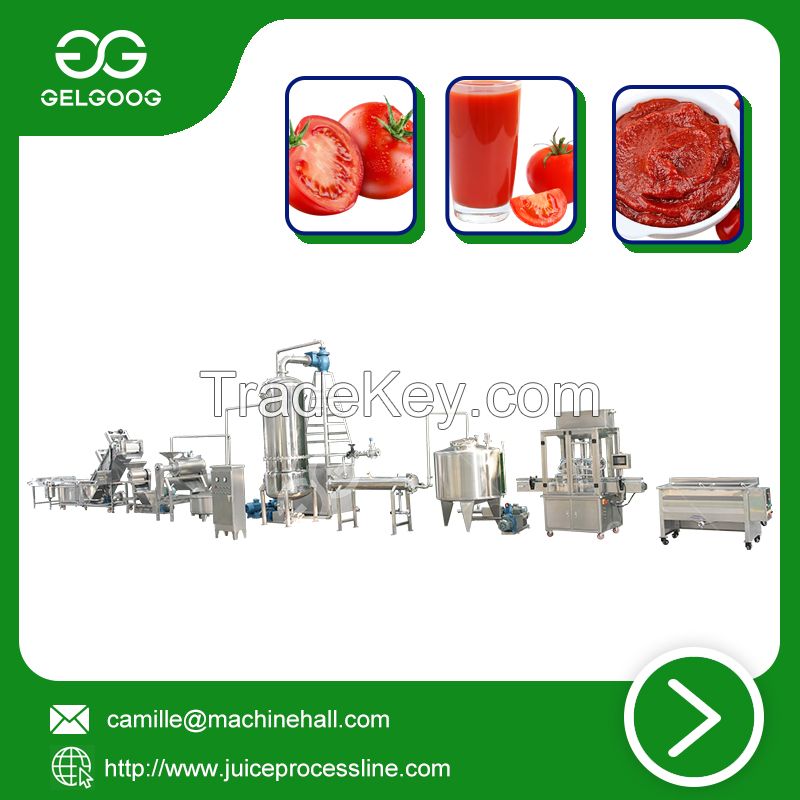

Tomatoes are generally processed into tomato sauce or

tomato juice. The ketchup has a bright red body. The unique feature

of ketchup is that it can be a very distinctive condiment.

Restaurants such as KFC and McDonald's use ketchup as a

condiment.

Process method of tomato sauce production

line

Ketchup is made by crushing, beating, removing the hard

materials such as skin and seeds, then shrinking, filling and

sterilizing ripe red tomatoes. Ketchup is often used as a cooking

condiment for fish, meat and other foods. It is a good seasoning

for adding color, adding acid, helping freshness, and

fragrant.

Components of tomato sauce production

equipment

The tomato sauce production

line includes raw fruit lifting system, cleaning

system, sorting system, crushing system, preheating enzyme-killing

system, beating system, vacuum concentration system, sterilization

system, and aseptic big bag filling system.

Ketchup parameters

The concentration of the product after the machine

processing of tomato sauce is: ****0% Brix, ****2% Brix, ****8%

Brix (can be adjusted according to customer product

indicators)

Initial Brix: 4.5%~5.5%

Discharge sugar content: ****0%, ****2%,

****8%

Packaging options: **0L aseptic big bag, tinplate can,

glass bottle, stand-up pouch

Technological characteristics of tomato sauce

production line

1. The tomato sauce can be used for concentration

processing only if the solid content is greater than 4.0%. Tomato

maturity must reach *0% or more.

2. When crushing is pre-cooked, it is heated quickly

and evenly. Seed removal is to prevent the seeds from breaking

during beating. If mixed into the pulp, it will affect the flavor,

texture and taste of the product.

3. Pre-cooking makes the tomato puree after crushing

and removing the seeds quickly heated to *5C~*0C to inhibit the

activity of pectin lipase and apolactamase, so as not to reduce the

price and denaturation of pectin substances.

Low viscosity and spreadability of

sauce.

4. The concentrated

sauce must be heated to *0C~*5C and then filled into cans. The

containers include tinplate cans, toothpaste-shaped plastic bags,

and glass bottles. Plastic cups or toothpaste-shaped plastic tubes

are currently used, and tomato sauce is packaged as a seasoning.

After filling the can, it will be vented and sealed

immediately.

| 国: | China |

| モデル番号: | - |

| 离岸价格: | ( Negotiable ) Get Latest Price |

| ロケーション: | China |

| 最低注文量の価格: | - |

| 最低注文量: | 1 Set |

| パッケージの詳細: | Standard pacakges |

| 納期: | 15 days |

| 供給能力: | 100 Set per Month |

| 支払いタイプ: | T/T, L/C, Western Union |

| 製品グループ : | Fruit and vegetable juice making machine |