FOB Price

Get Latest Price|

Minimum Order

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

-

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

-

Payment Type:

-

連絡先担当者 Jack

Shanghai, Shanghai

Process and In-Line XRF Analyzer

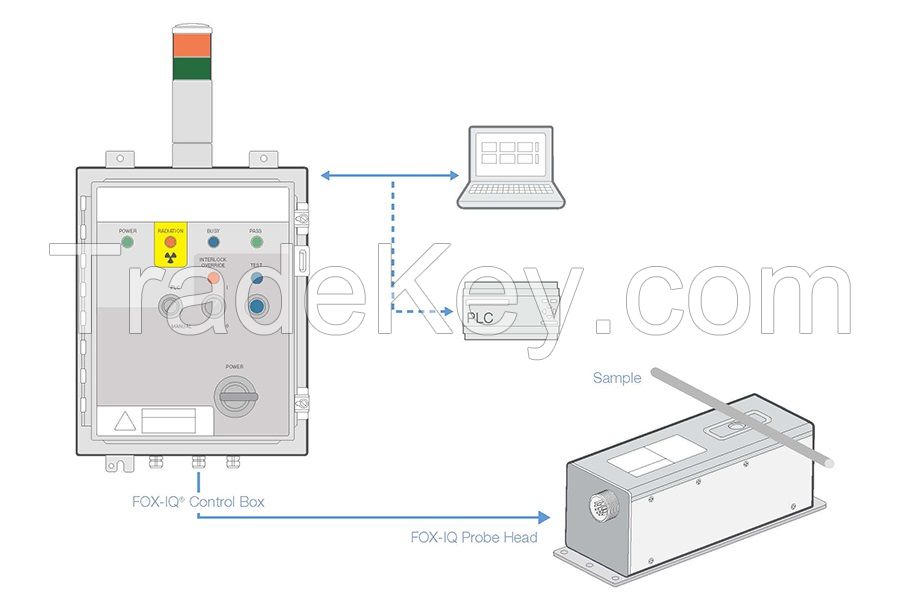

On line analyzer provides customizable, continuous measurements of

titanium (Ti) to uranium (U) on any surface. Designed to operate

*4/7, the XRF system performs fully automated in-line analysis for

**0% high-volume process control.

X-ray fluorescence (XRF) is a proven technique used to quickly and

nondestructively verify alloy grade and chemistry. The system is

compact and has minimal power requirements, making it easy to

integrate with new or existing PLC-controlled processes. The system

is engineered to endure high levels of vibration, electromagnetic

and acoustical noise, dust, and moisture.

Each system delivers pass/fail results, accurate grade

identifications, and material chemistry. It can be controlled by a

PC or integrated with a PLC for automated start/stop, data

acquisition, decision-making, and communication to external

devices.

Quickly Analyze and Compare Alloy Tubes and Rods to

Specification

The system can be configured for fully automated alloy testing with

data logging and alerts.

Typical Applications:

•**0% heat or batch alloy type verification

•Quality control of components after the fabrication process

•Use in service centers to confirm alloy type before shipment

•Alloy types: stainless steels, carbon steels, low-alloy steels,

tool steels, nickel alloys, nickel-cobalt alloys, titanium alloys,

zirconium alloys, copper-nickel alloys, brasses, bronzes, and

aluminum alloys